When businesses look to extend the life of their metal assets, they turn to Rocket Powder Coating for industrial powder coating services. More than a cosmetic upgrade, powder coating provides a strong, durable finish that protects machinery, structural parts, and equipment from harsh environments. Over time, that protection translates into real cost savings by minimizing repairs, repainting, and downtime.

Rocket Powder Coating combines years of experience, advanced equipment, and a relentless focus on quality. Serving companies throughout Minnesota and Wisconsin, they deliver industrial finishes that endure rigorous conditions. Whether a business needs small custom parts or large-scale components coated, their capacity and expertise make them a go-to partner.

What Is Industrial Powder Coating?

Industrial powder coating applies a dry, finely ground powder to metal surfaces and then cures it under heat. During the curing process, the powder melts and chemically bonds to the substrate, forming a tough, resilient layer. Unlike traditional liquid paint, this method produces a uniform coating that resists chips, fading, and corrosion—even in demanding industrial settings.

Rocket Powder Coating uses commercial-grade electrostatic application tools to ensure precise coverage. Their facility handles parts of all sizes, from small brackets to massive structural pieces, and delivers consistent results for short runs or high-volume production.

Protection Against Corrosion and Wear

A major advantage of industrial powder coating services is the corrosion resistance they provide. Powder coating forms a tight, non-porous barrier that prevents moisture, salt spray, and industrial chemicals from reaching the underlying metal. This barrier significantly reduces the risk of rust and degradation, helping equipment last longer.

Powder-coated surfaces resist abrasion and impact better than many painted alternatives. The finish withstands daily handling, contact, and stress without chipping or cracking, which reduces maintenance and replacement costs.

Reducing Lifecycle Costs for Your Business

An initial powder-coating job may cost more than a basic paint job, but it often pays for itself. Because the coating is so durable, parts don’t need to be repainted or touched up as frequently. That translates into real savings in labor, materials, and downtime.

Fewer repairs also mean less disruption to production. When parts last longer, your team spends less time waiting for replacements or rework. Over time, the durability of industrial powder coating helps businesses reduce their maintenance burden and increase uptime.

Efficiency Through a Proven Process

Rocket Powder Coating’s process is designed for both quality and speed. They begin every project with a consultation to understand your goals, volume, and finish preferences. Then they prepare metal parts using sandblasting or other methods to remove rust, old coatings, and debris. Proper preparation ensures the powder adheres correctly, creating a long-lasting bond.

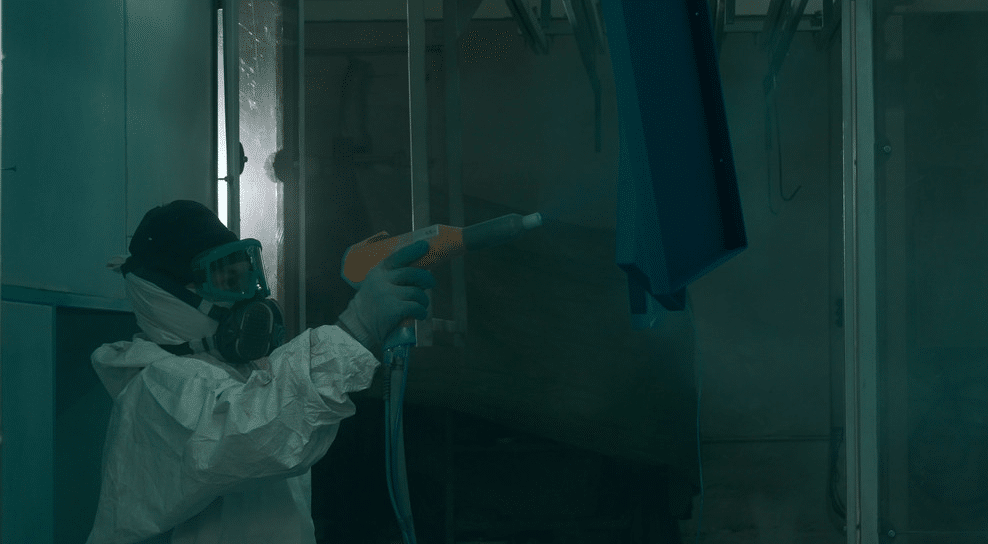

Once prepped, parts are masked to protect areas that should remain uncoated. Then the team uses electrostatic spray guns to apply the powder evenly. After application, each piece is cured in a specialized oven, transforming the powder into a dense, cross-linked coating. After curing, every item undergoes a rigorous inspection to ensure it meets high standards. Finally, parts are carefully packaged and returned, ready to use.

Custom Finishes to Match Your Needs

Not all industrial projects are the same, and Rocket Powder Coating offers a wide range of finishes to match different requirements. Businesses can choose from matte, gloss, textured, or metallic looks to meet both performance and design needs. Custom color matching ensures that finishes align with brand identity, safety color codes, or aesthetic preferences.

Whether it’s manufacturing machinery, architectural metalwork, or equipment for transportation, powder coating delivers both style and strength.

Restoring and Refurbishing Existing Equipment

Industrial powder coating isn’t just for new parts. Many businesses use the service to restore older equipment. Rocket Powder Coating strips worn or rusted surfaces, preps them thoroughly, and applies a fresh, durable finish. The result is metalwork that looks and performs like new—with a protective layer that can handle industrial abuse.

This refurbishment option often costs less than replacing parts entirely. It’s a smart way to extend the life of your investment without cutting corners.

Sustainability That Helps Your Bottom Line

Powder coating is also an environmentally sound choice. Because it contains no solvents, it emits very low volatile organic compounds (VOCs), which makes it safer for your team and better for the air. According to PPG, powder coatings can achieve a material utilization rate of up to 98 percent, meaning very little is wasted.

Because overspray can often be reclaimed and reused, the process produces less waste than traditional liquid painting. This efficient use of materials contributes to long-term cost savings and environmental responsibility—benefits that align well with modern business values.

Durability That Outperforms Traditional Paint

Compared to traditional paint, powder coating delivers superior durability and toughness. The cured surface is highly resistant to scratching, chipping, and fading under stress. This strength comes from the way powder cures into a dense, cross-linked film, making it ideal for industrial applications.

Additionally, powder coatings perform exceptionally well in environments exposed to UV, chemicals, or moisture. As a result, coated components maintain their integrity and aesthetic appearance for many years longer—with less need for touch-ups or full recoats.

Why Local Businesses Trust Rocket Powder Coating

Businesses across Minnesota and Wisconsin rely on Rocket Powder Coating because it delivers quality, speed, and reliability. Their skilled technicians have deep experience in industrial finishing, and their equipment is up to the task for even challenging jobs.

They serve a wide range of industries, including manufacturing, transportation, construction, and more. No matter the project size or complexity, Rocket Powder Coating brings the same commitment to excellence, ensuring your parts are finished with precision.

The Process You Can Trust

- Consultation & Assessment: The team talks through your project needs and volume.

- Surface Preparation: Metal parts are cleaned and prepped to guarantee proper adhesion.

- Masking: Sensitive areas are masked so they do not receive coating.

- Powder Application: Using an electrostatic spray, powder is evenly applied.

- Curing: Coated parts are baked in a curing oven until the finish fully bonds.

- Inspection: Each piece is carefully checked to meet high standards.

- Packaging & Delivery: Finished items are handled with care and returned ready for use.

This reliable process ensures that each job—whether large or small—meets Rocket Powder Coating’s strict quality standards.

Choose Rocket Powder Coating for Reliable Results

Companies looking for industrial powder coating services that offer protection, value, and customization should choose Rocket Powder Coating. Their process enhances equipment durability, cuts down maintenance costs, and delivers finishes that perform under pressure.

Protect your assets, reduce your long-term expenses, and invest in quality. Reach out to Rocket Powder Coating today for a free consultation and learn how their powder coating services can support your business goals.